LVL Corner

Ask us for the best in LVL

In a few months' time, our plant in France will be producing a biosourced building material to help meet greenhouse gas emission reduction targets.

The technological choice was LVL, a high-performance engineered wood product for demanding applications, particularly in the construction sector.It will be marketed under the brand name TEBOLVL®. Our commitment: to transform a noble material into a virtuous one.

The first LVL produced in France from a local resource

Mechanically efficient, TEBOLVL®offers higher raw material yields. It stores carbon sustainably and plays an important role in combating climate change. Our plant is located in the immediate vicinity of the Auvergne massif, which offers an abundant and managed resource of pectin fir. Pectin fir used in the manufacture of TEBOLVL®has all the characteristics required to meet the specifications of standard EN 14-374. What's more, it offers a high-quality visual appearance that sets it apart from other softwood products.

Choosing technological excellence

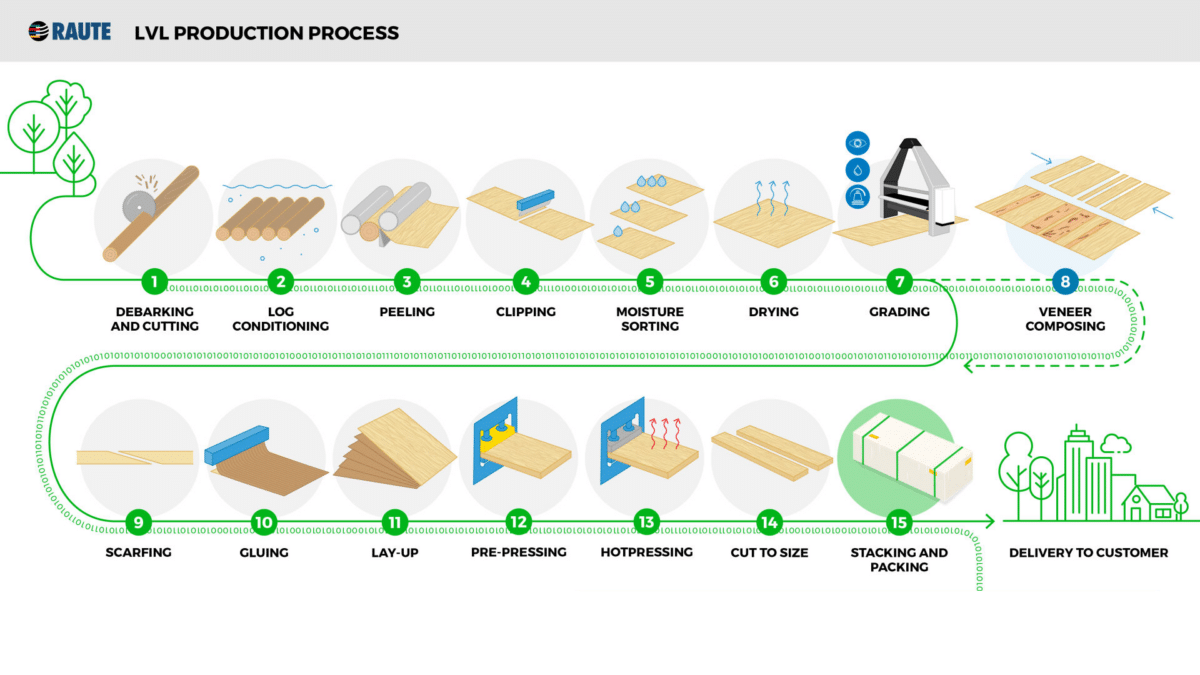

The Finnish company RAUTE, a leading provider of technology and services in the wood products sector, was chosen to equip the machines. RAUTE is the world leader in the plywood and LVL industry. More than half of the world's LVL is produced on RAUTE-supplied machinery.

The diagram below describes the manufacturing process (Source: RAUTE).

A response to construction requirements

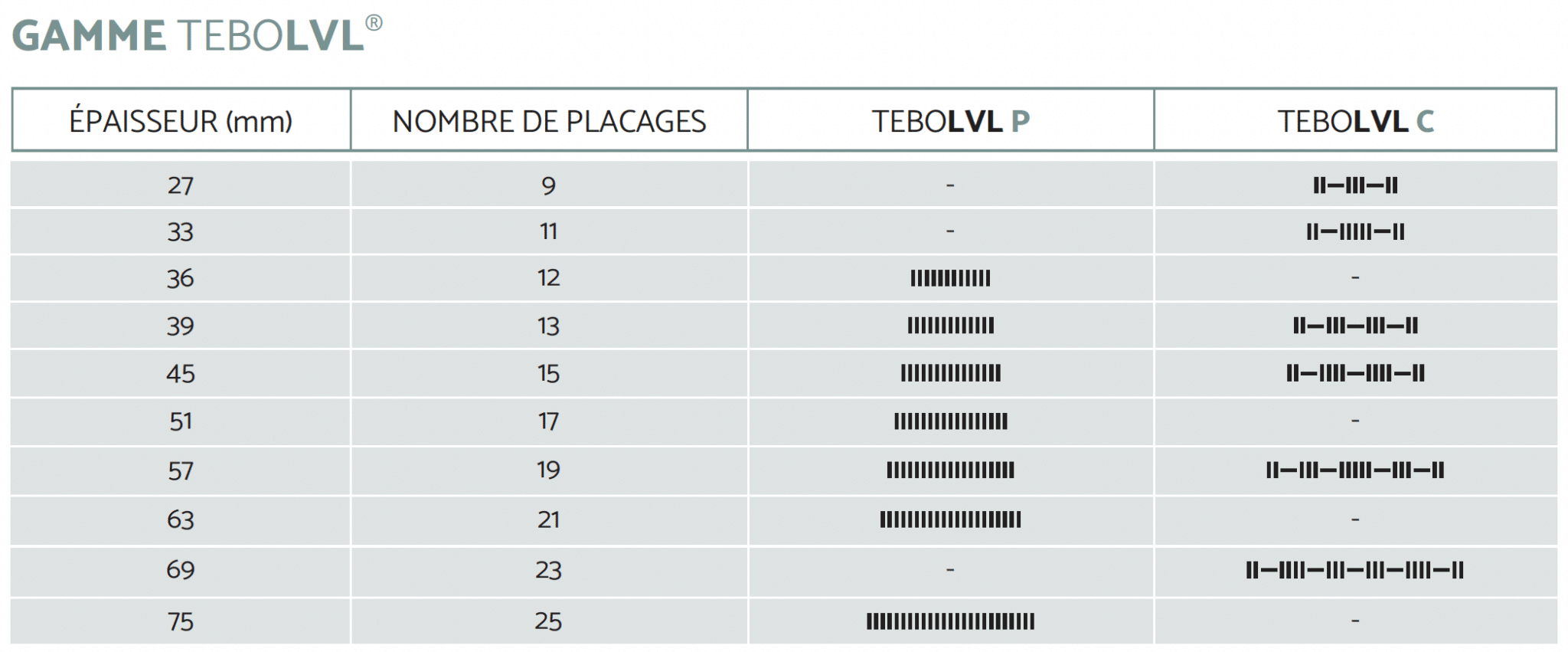

TEBOLVL®is a demanding engineered wood product designed for structural building applications. The panels are made from peeled veneers of French spruce. The 3 mm veneers are then superimposed and assembled with "scarfed" and staggered joints. High-pressure hot-gluing completes the manufacturing process.

Depending on the skills required, we offer two solutions.

TEBOLVLP, for Parallèle, is produced with all veneers oriented in the same direction. It is suitable for most "horizontal" applications, such as beams and framing.

TEBOLVLC, for Croisé, is assembled with 20% 90° veneers, which reinforces its dimensional stability in all directions, without sacrificing its mechanical properties. It is intended for the manufacture of high-strength constructive components and for "panel" use.

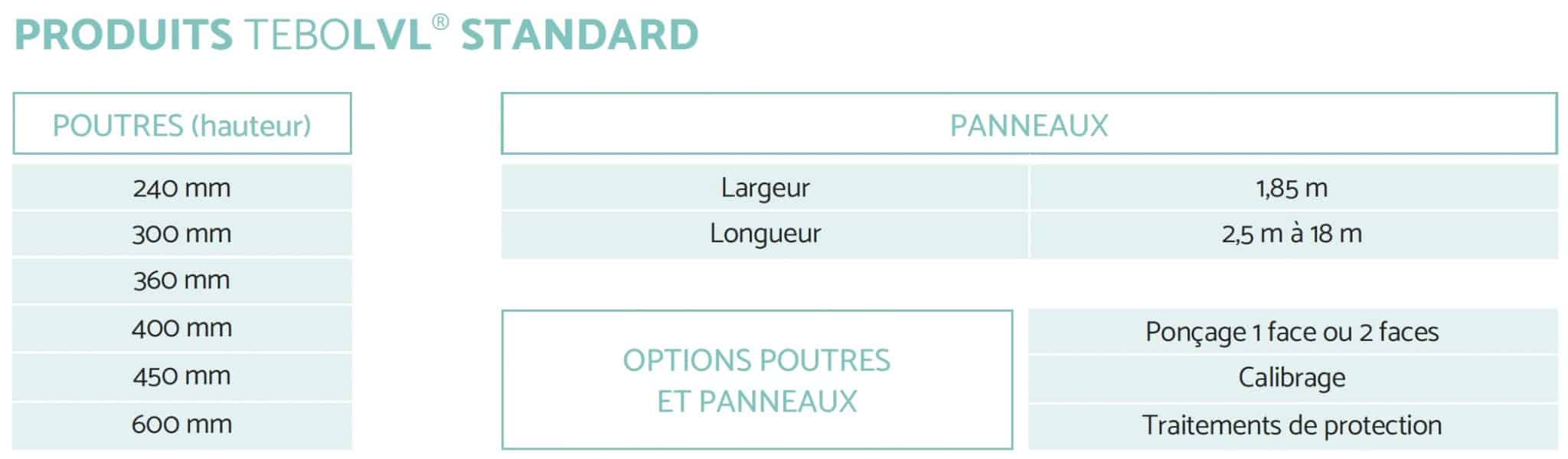

Ask for standard and custom sizes

TEBOLVL®is available in all the usual formats for easy implementation in beam or panel applications. Customized formats are available to meet specific customer requirements.

TEBOLVL® also offers finishing options such as 1-sided or 2-sided sanding for "exposed" applications. Finally, protective treatments are available to enhance durability, particularly in outdoor applications.

Our future plant will stock standard products, which can be dispatched to the trade or on site as quickly as possible.